MOD. MT/PK (Pick & Place)

The automatic capper MOD. MT/PK (Pick and Place), maximum production 2.500 b/h, is conceived for the application of pre-threaded plastic caps on P.E.T. bottles, with adjustable height and diameter. The caps are fed through a circular vibrating feeder and distributed to the Pick & Place transfer system. The magnetic head takes the cap with the positive seize, it releases the Pick & Place and then applies it to the bottle. The machine is provided with a magnetic head for pre-threaded caps and it is operated by a variable speed motor in order to increase or decrease the revolutions of its rotation. The format change and the height adjustment are rapid and simple.

MOD. MT/CX

The automatic capper MOD. MT/CX, maximum production 2.500 b/h, is conceived for the application of crown caps with a diameter of 26 or 29 mm. The machine is apt to process cylindrical glass bottles with adjustable diameter and height. The mechanical head lifting is operated manually with a hand wheel and it allows to handle different shapes of bottle.

The crown cap is fed through an automatic vibrating feeder with stop/start photocell with full chute in order to prevent any aesthetic damage. Special security systems stop the machine immediately in case of anomalies, preventing any breakages of bottles or other inconveniences.

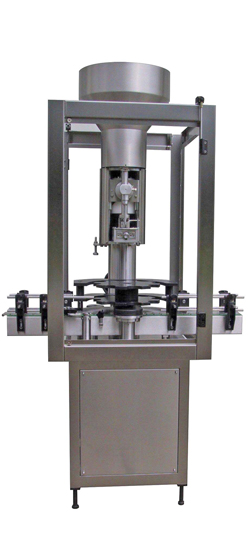

MOD. MT/SR

The automatic corker MOD. MT/SR, conceived for the application of wine cork caps, is made of stainless steel AISI 304, steel alloys and food-graded plastic materials which make the maintenance and the cleaning and sterilizing operations easy, ensuring a long life to the machine. The format change and the height adjustment are quick and simple, the head lifting is mechanical with adjustable height. The closing system of the corking group has four blocks made of tempered and rectified stainless steel with centesimal tolerance and it is easy to disassemble for the cleaning and sterilizing operations. Special security systems stop the machine immediately preventing any breakages of bottles or other anomalies.

MOD. MT/VX

The automatic capper MOD. MT/VX, conceived for the application of plastic pressure caps and aluminium screw caps on glass bottles (the cap is positioned in the centering device and then automatically pressed on the bottle), is made of stainless steel AISI 304, steel alloys and food-graded plastic materials which make the maintenance, the cleaning and sterilizing operations easy, ensuring a long life to the machine. The format change and the height adjustment are quick and simple, the head lifting is mechanical with adjustable height. The machine is provided with a vibrating cap feeder. Special security systems stop the machine immediately preventing any breakages of bottles or other anomalies. All the electrical controls and the safety devices are manufactured in compliance with the norms in force.

MOD. MT/FP

The corker MOD. MT/FP, conceived for the application of plastic champagne caps and T-shaped plastic/cork caps, is manufactured in stainless steel AISI 304, steel alloys and food-graded plastic materials which make the maintenance, the cleaning and sterilizing operations easy, granting a long life to the machine. The head lifting is mechanical with adjustable height. The machine is provided with a vibrating cap feeder. Special security systems stop the machine immediately preventing any breakages of bottles or other anomalies. All the electrical controls and the safety devices are manufactured in compliance with the norms in force.